Distiller’s Dried Grains with Solubles (DDGS) is a processed grain by-product from the Ethanol production process from grains like corn, wheat, or barley, but mostly corn. Essentially, it’s the dried residue left after fermenting grains to produce ethanol. After starch is fermented into ethanol, the remaining grain fraction is dried and blended with solubles to create DDGS. It had become a significant feed ingredient for cattle, poultry, and swine worldwide due to its nutritional value and cost-effectiveness.

DDGS contains residual oils that may oxidize, leading to self-heating in bulk if the moisture is high. Its quality often varies depending on the plant, processing, and storage before shipment.

DDGS from U.S. – Global Shipment & Statistics

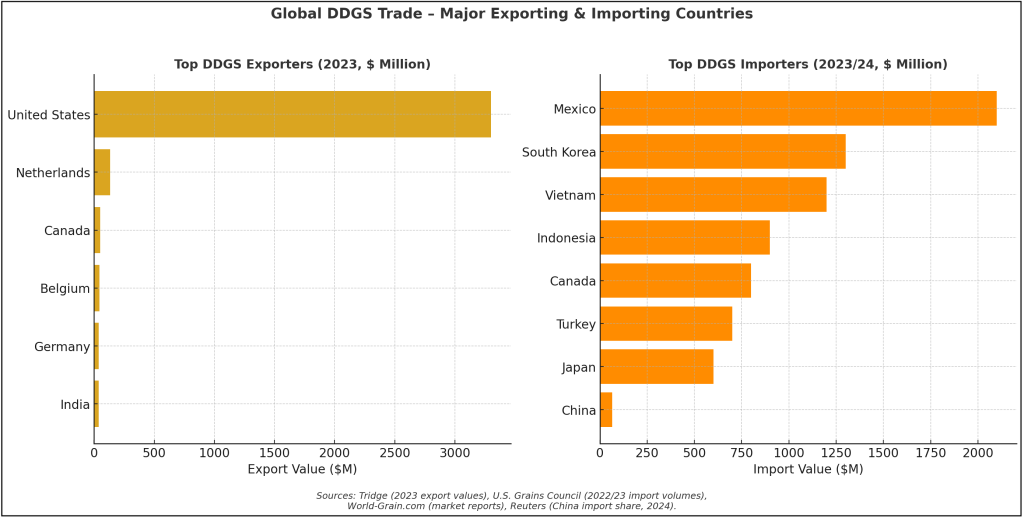

The United States (U.S.) is the dominant exporter of DDGS, accounting for about 84% of global exports, leading by a wide margin in volume and value, followed by European countries and Canada, which contribute minimal shares by comparison.

The data (Figure 1) below (as per the included references) establishes that the U.S. is the largest exporter of DDGS, shipping millions of tons annually, with major global importing countries.

Figure 1: U.S. DDGS trade and major importing countries

Figure 1: U.S. DDGS trade and major importing countries

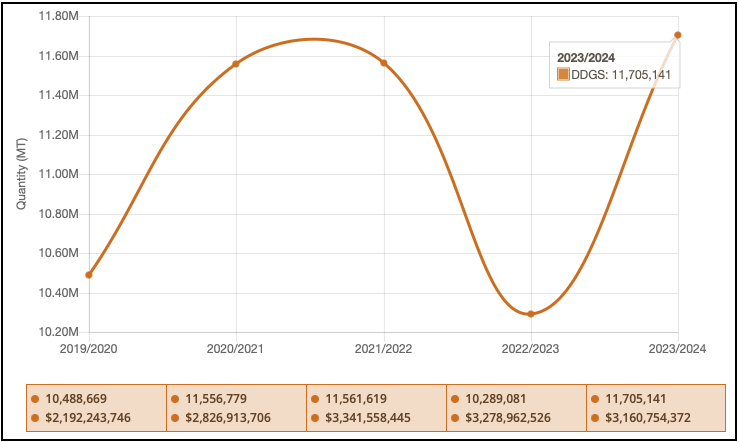

Figure 2 below (sourced from U.S. Grains and Bioproducts Council) documents the yearly quantity of DDGS exported from the U.S.

Figure 2: Yearly DDGS export from the U.S. (sourced from U.S. Grains and Bioproducts Council)

Figure 2: Yearly DDGS export from the U.S. (sourced from U.S. Grains and Bioproducts Council)

Understanding U.S. Regulations for DDGS

The United States Department of Agriculture (USDA) has an important but limited role in the export of DDGS. The USDA does not guarantee the merchantability of DDGS, does not establish commercial specifications between buyers and sellers, and is not liable for any deterioration or damage to the cargo after loading.

DDGS shipped from the US is not treated as “Grain” under the US Grain Standards Act (USGSA) and is therefore not traded under official US grain grades. Instead, DDGS is handled as a processed grain product under the Agricultural Marketing Act (AMA), which uses the USDA’s Official Commercial Inspection Services (OCIS) if the trading parties request official testing. The USDA’s function is to act as a neutral third party under the AMA, with primary responsibility for providing independent inspection, sampling, and certification services that support fair trade and meet regulatory requirements.

It is essential to understand that the US Grain Standards Act (USGSA) should not be confused or misinterpreted for the carriage of DDGS, as:

- USGSA covers only official “export grain” such as wheat, corn, soybeans, etc.

- DDGS is a processed byproduct, not a whole grain, and hence is not included in the USGSA Grain list.

- No official U.S. grade standards exist for DDGS.

International Grain Code & DDGS

The International Code for the Safe Carriage of Grain in Bulk (Grain Code) defines grain in bulk as wheat, maize (corn), oats, rye, barley, rice, pulses, seeds, and other similar cereals plus products derived in whole or in part from such grains, when they behave like grain in stowage.

The Grain Code does not include DDGS, but it is classified under the properties of grain, as it behaves similarly to grain in terms of flow and handling, which implies that vessels loaded with DDGS will require applicability of the Grain Code for:

- Grain stability calculations (heeling moments, grain stability booklet)

- Trimming and securing requirements

- The grain loading document(s) onboard a vessel may list DDGS under grain cargo

Quality & Testing Criteria for DDGS

In the U.S., there is no single governmental authority that sets uniform, legally binding DDGS acceptance and testing criteria. A combination of federal feed safety regulations, industry guidelines, and commercial contracts determines the standards for DDGS.

However, the U.S. Food and Drug Administration (FDA) regulates DDGS and other feed ingredients under the Food Safety Modernization Act (FSMA).

For commercial trade of DDGS, specific acceptance and testing criteria are most often defined in the commercial contract between the buyer and the seller. These agreements typically outline acceptable ranges for:

- Moisture content

- Physical properties

- Contaminants

- Nutrient levels

Table 1 below summarizes the standard and routine industry standards applicable to testing and acceptance of DDGS

|

Test Parameter |

Testing Method & Standards |

Acceptance Range |

|

Moisture |

Oven-dry, USDA laboratory |

≤ 12% |

|

Crude Protein |

Kjeldahl/NIRS |

25% to 36% |

|

Crude Fat (Oil) |

Ether extract |

3% to 10% |

|

Fiber |

Crude fiber/NDF |

< 14% |

|

Sulfur |

Wet chemistry |

≤ 0.7% |

|

Mycotoxins |

ELISA/HPLC (DON, Fumonisins, ZEA, Aflatoxins) |

As per the DDGS importer’s specification |

|

Insects |

Visual + USDA phytosanitary |

None permitted |

|

Odor |

Organoleptic |

Clean, neutral only |

Table 1: Common parameters tested for DDGS and acceptance criteria

Risk & Challenges in Shipping DDGS

DDGS, when loaded in bulk, can be considered off-spec due to various factors and concerns as listed in Table 2 below.

|

Factors Affecting DDGS |

Concerns |

|

Moisture Content |

DDGS is hygroscopic. Moisture content > 12% increases the risks of caking, mold growth, and heating during shipment of DDGS.

For ocean carriage, low and stable moisture content is recommended. |

|

Contamination |

|

|

Nutrient Levels |

|

|

Mycotoxins |

Corn-based DDGS may carry DON (Vomitoxin), Fumonisin, and Zearalenone (ZEA), which, even at low levels in animal feed, can reduce animal performance and trigger rejection of cargo. |

Table 2: Primary quality concerns related to DDGS cargo

DDGS Cargo Color Concerns in Global Trade

The color of DDGS has become a significant quality factor for international buyers. The color of this cargo has become a controversial issue. It is incorrectly used to differentiate between real and perceived quality and value among DDGS sources, leading to significant cargo rejection and claims.

Many DDGS contracts that are negotiated between U.S. suppliers and buyers, primarily in Asian countries, contain a minimum guarantee for a quantitative measure of color (lightness or darkness of color), using the Hunter lightness l-a-b color code (L). {L value quantifies a color’s brightness on a scale of 0 (black) to 100 (white)}. The minimum guarantee currently being used to differentiate the lightness of DDGS color is a Hunter Colorimeter’s color scale (L) greater than 50 to meet some buyers’ expectations for light colored cargo.

The color of DDGS is not a reliable indicator of its quality and nutritional value. Moisture, mycotoxins, protein, and other lab-tested factors are more reliable. Still, color is the first visual red flag many buyers use when assessing shipment quality

Table 3 below is adapted from feed industry buyer specifications and U.S. Grains Council guidance, which is often used as an informal DDGS color shade guide.

|

DDGS Color |

Appearance |

Interpretation in Trade |

|

Light Yellow

|

Bright golden, free-flowing | Preferred due to high digestible lysine |

|

Yellow Orange

|

Slightly darker, uniform | Acceptable, common in bulk trade |

|

Brownish Yellow

|

Darkened edges, uneven shades | May indicate overheating, reduced protein value |

|

Dark Brown

|

Burnt odor, clumped | Often rejected or discounted |

Table 3: DDGS color/shade interpretation

DDGS Inspections in the U.S.

DDGS shipped from the U.S. is a commodity not covered under the U.S. Grain Standards Act, but is handled as a processed grain product under the Agricultural Marketing Act, utilizing the USDA’s Official Commercial Inspection Services (OCIS), only if the commercial trading interests request official testing.

OCIS is not utilized for export grain grades, but it is the standard USDA pathway when a commercial trade requires official, third-party quality results on DDGS against contract specifications. OCIS allows commercial interests to specify which tests to run (e.g., moisture, protein, oil, fiber, ash, mycotoxins) and how to sample DDGS cargo.

OCIS testing and certificates are optional and are based only on the merit of the commercial contract or the chartering terms.

Fumigation & Phytosanitary Certification

DDGS cargoes are often fumigated after loading, but it’s not implied or mandatory in every cargo loading. Fumigating cargo holds loaded with DDGS entirely depends on importing countries’ requirements, charter party terms, and the condition of the cargo. It is strongly advised to clarify these details with the shipper before loading the cargo, as DDGS is prone to insect infestation due to self-heating properties, moisture, and during extended voyages, as these conditions are considered suitable for mold/infestation.

If the importing country requires a phytosanitary certificate for DDGS, then the Federal Grain Inspection Service (FGIS) can perform the phytosanitary inspection of the DDGS loaded in cargo holds. Based on an inspection conducted by FGIS, the Animal and Plant Health Inspection Service (APHIS) will issue a phytosanitary certificate.

Sampling Method for DDGS

DDGS is considered a dense and processed product. Hence, DDGS cargo loaded in cargo holds must not be sampled using a cargo sampling probe. DDGS should be sampled using online sampling methods, such as the pelican, Ellis cup, and diverter-type mechanical samplers, to ensure the drawn samples are representative.

Key Takeaways for Shipping DDGS from U.S.

With our years of experience and expertise, we always advise the vessel owners/interests to:

Obtain contracted details of DDGS export cargo from the shipper, including, but not limited to:

- Agreed and contracted specifications for DDGS, including percentage of moisture, protein, oil, fiber, and foreign material limits.

- Verify and ascertain if a USDA OCIS testing (and type) is mandated or requested by the buyer or cargo receiver.

- Requirements for a phytosanitary certificate

- If any color scale (like Pantone color scale) is required for the DDGS cargo

The vessel’s interest should confirm the requirements for any certification, as per the trade agreement and applicability:

- FGIS OCIS Certificate of Quality

- FGIS Stowage Exam Certificate

- Phytosanitary Certification

U.S. DDGS- Best Practices for Shipowners

It is not uncommon for DDGS cargo to be subjected to caking and lump formation, which, when loaded in cargo holds, seldom appears as large, hard lumps throughout the cargo or in pockets. These lumps can be formed due to compaction during transportation in barges or during stowage. During loading, the crew should be easily able to pulverize these DDGS lumps. However, if the lumps are very hard, moist, dark brown in appearance, and odor, the crew should consider further investigation and seek immediate advice.

During loading, DDGS cargo loaded in holds is seldom found cross-contaminated with other grades of grains. Depending on the nature and type of cross-contamination, which is not uncommon, the vessel should seek professional advice and guidance.

If the DDGS cargo is exposed to rain during loading and is wet, the vessel should stop cargo operations and request that the stevedores remove the affected cargo under protest, in the presence of their P&I surveyor. Since DDGS has high oil content, any residual moisture can self-heat during the extended voyage, compounded by poor ventilation and compaction in loaded holds.

It is critical to remember that, based on the carriage requirements and fumigation, inadequate or incorrect ventilation during an extended voyage can affect the cargo loaded in the holds. Hence, the vessel must be very careful of the relative humidity and Dew Point during the voyage and before any ventilation.

In the event of any potential or known concerns or a need for guidance, a vessel operator should seek professional assistance from a qualified P&I surveyor. This assistance may include taking various cargo samples at different stages of loading, generating photographic evidence, and sealing the cargo holds (if required) before departure. During the voyage, the vessel must maintain a detailed log/records of bilge soundings, weather conditions, and any ventilation of holds, if required.